Improving Nutrient Value of Byproducts

Oct. 23 | 2016

Producing silage is one method of treating low quality crop residues. Silage consists of cut plant material that is sealed in a silo without air and water. Silage can be stored for many months and still have up to 85% of the energy and protein value of the original fodder crop. Low quality crop byproducts, such as maize or wheat straw, treated with urea is an easy method to increase digestibility and productivity of livestock. It is commonly done below the ground in lined pits or above the ground in bags. After mixing urea, water and straw, the pits are sealed for at least 3 weeks. The treatment of crop residues can be done any time as long as the residue, water and urea required for the treatment are available. The best period recommended, however, is just after harvest as the forage supplies are readily available at this time.

Ammonia is released through urea degradation done by the action of microorganisms. These microorganisms are normal inhabitants of low quality roughage and produce urea in the presence of moisture. With adequate moisture and suitable temperature, urea is degraded to ammonia which then permeates through and binds the straw.

The nitrogen is released through the process and is used as the building block for the production of protein by the animals’ digestion process and the rumen microbes. The treated roughage will be significantly higher in digestibility and crude protein than the untreated material.

This is important as sheep and goats will not maintain body condition or produce milk on a low nutrient, roughage heavy diet. Purchased supplements to improve nutrition are usually not available or an economical option for the small farmer. This method uses locally available products and family labor.

Why Urea?

Fertilizer grade urea is readily available in many developing countries. It improves the nutritional quality of roughage such as tough crop residue and is a very simple and effective process to improve the intake of poor quality feed.

A family of 4 can treat about 1 ton of straw in 4 hours!

Method:

Suggested level of urea is 5 kg per 100 kg of material. The moisture level in the roughage determines how much water should be added may range from 0.3 to 1 liter of water per kg straw. The moisture level can be estimated by handling. Dry (95%) will be brittle, whereas wet (85%) will be sticky and bend in hand.

Urea is weighed and dissolved in a measured quantity of water. Then the urea-water solution is sprinkled on the residue and added to the pit in batches. Removing air from the pit is important and involves packing before covering with plastic, or leaves such as banana, and then soil.

Crop residues such as bush straw, corn stalks, sorghum stover, or rice straw are commonly used. The residues from corn stalks or sorghum stover should be chopped to provide a greater surface area for the treatment process and to increase subsequent intake by the animal.

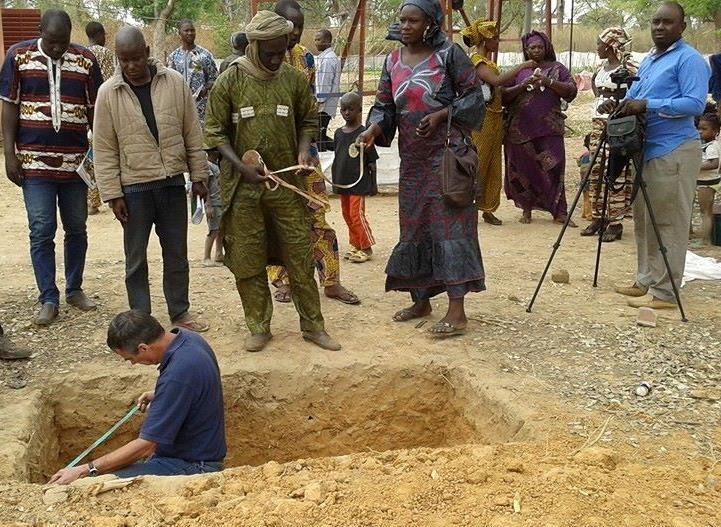

There are many different designs of pits or trenches for urea treatment. A common recommendation is 1 m wide, at least 2 m long and 1 m deep and will typically hold between 150 to 200 kg of roughage with the top of the pile being slightly above ground level (see above).

It is useful to construct more than one adjacent pit so that treated roughage from one pit can be used while the next pit is being treated. This helps to ensure continuous supply.

Apart from pits or trenches plastic bags (see cassava silage project, page 9) that can hold 20 to 25 kg of treated straw may be used. Such bags have the advantage in that individual bags can be opened when needed to feed animals and resealed to prevent mold contamination.

Why Silage?

Silage has 3 main roles:

- To build up feed reserves for utilization during periods of feed deficiency, e.g. dry season.

- As a routine feed supplement to increase productivity of animals.

- To utilize excess growth of pasture for better management and extended utilization.

Silage quality is maintained for longer than is hay quality, because hay oxidizes during storage. Thus silage is better as a fodder bank than is hay.

Recommendations:

It is recommended that farmers feed urea-treated roughage to their animals with the highest nutritional requirements, such as lactating or fattening animals.

Other farmers may find it beneficial to feed limited amounts of the treated roughage as a supplement, with the remainder of the animals’ diet being untreated roughage or grazed forage.

It is preferred to begin urea treatment when crop residues are plentiful before needed during the dry season.

Finished Silage Pit With Farmer Cooperative Members and Volunteer Terry Gipson